SMS Concast, part of the German plant SMS group, has received a major contract from Chinese steel manufacturer Henan Jiyuan Iron and Steel to modernize its No. 2 continuous caster. Originally built by a local manufacturer, the eight-strand continuous caster will undergo a complete modernization to achieve new standards of productivity and quality. Commissioning is scheduled for June 2026.

The purpose of the modernization is to improve product quality, increase product yield and improve the foundry's ability to process various grades of steel, especially high-carbon steels such as bearing and spring steels, as well as various steels for the automotive industry. Once commissioned, the plant will achieve an annual billet production capacity in excess of 1 million tons.

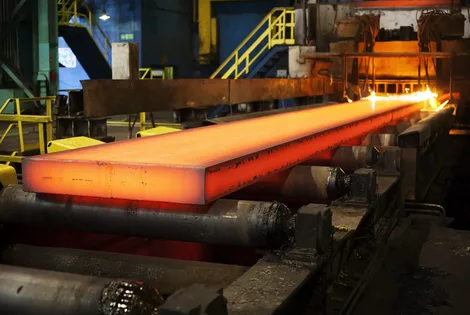

The caster has eight strands, a nominal radius of ten meters and is capable of processing billets in sections of 150 mm, 160 mm and 180 mm. More than 90 percent of the production balance will consist of SBQ and high carbon steels, which are key raw materials for downstream forging and production of automotive components.

The upgraded continuous caster will be integrated with SMS Concast's CONFLOW system to achieve precise control of steel feed into the mold, ensuring consistent internal structure and minimal central porosity; and the CONDRIVE oscillation system, which provides flexible electromechanical tuning, allowing operators to fine-tune oscillation parameters for different brands.